2-MINUTE EXPERT

Three Things About Suspension Oil

We can't see what's in our forks and shocks, which makes their inner workings a beautiful mystery of shims, valves, and pistons that help fuel the fun on two wheels. What's also lurking inside, though, are petroleum-based oils that are harmful to mechanics when not handled carefully, and harmful to the environment if not disposed of properly. We all know that taking care of our suspension is essential for a smooth-running bike that performs well, but in doing so, we should try to make choices about the products we use that are better for ourselves and the planet.

Let's cover a few things about suspension oil that - if you're like me - you probably didn't know before now.

Suspension oil weights are not standardized

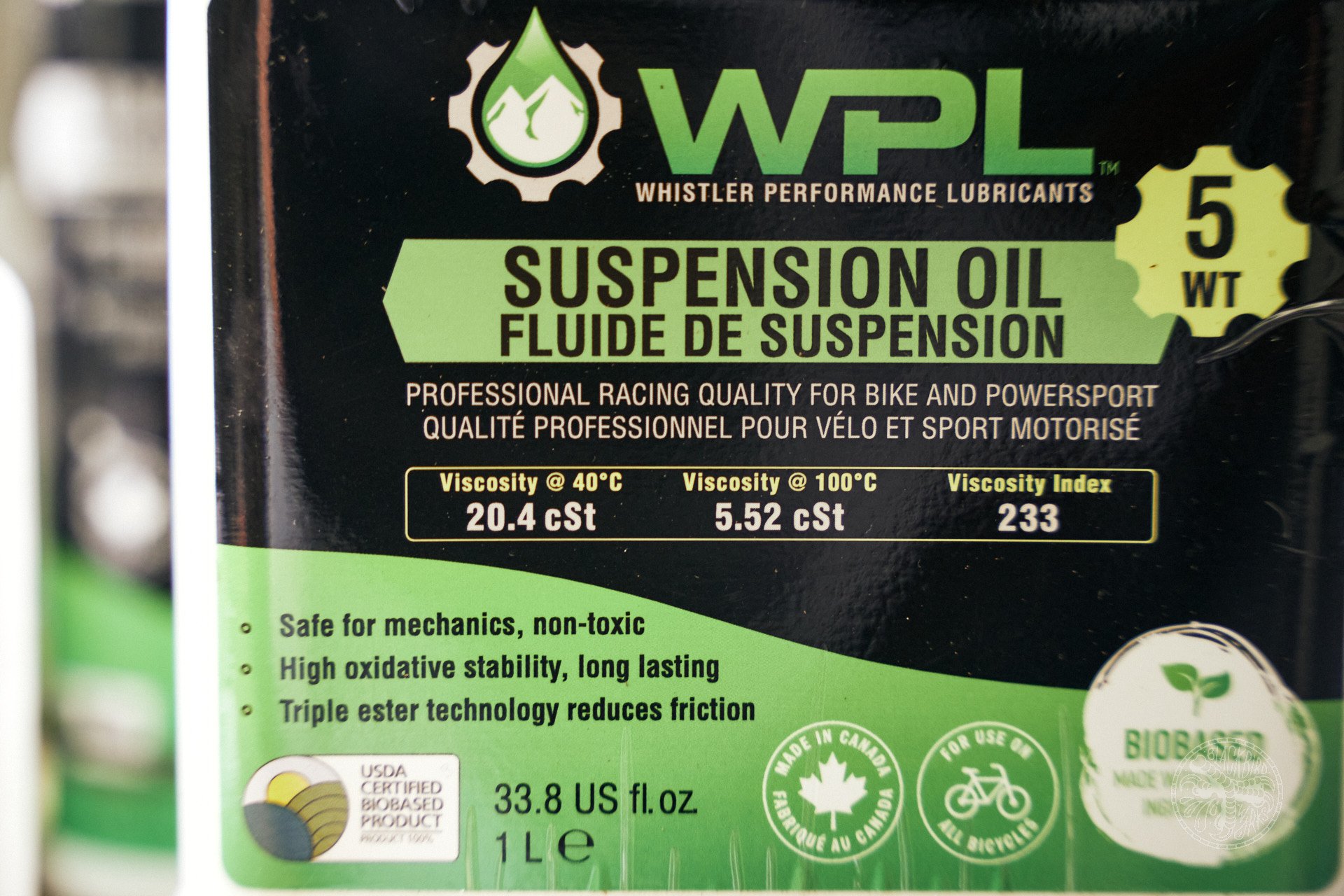

One brand's 5wt is not the same as another brand's 5wt, and anyway 'wt' or 'weight' isn't even an accurate way of measuring the performance of a suspension oil. If you take nothing away from the tech stuff below, it should be that if you're trying to pick what suspension oil to use, don't go by ratings that use 'wt' - it's not going to be that useful at least as far as comparisons across brands. The reasons behind this are beyond the scope of this article, but the basic gist is that the SAE weight system is inconsistent due to the way the SSU/VI systems are measured.

Let's review a few terms before we go further.

Viscosity is the resistance of fluid to flow, measured in square centimeters per second, aka centistokes (cSt). The Society of Automotive Engineering (SAE) uses cSt measurements and converts it to a weight value like 5wt, 10wt, which may sound familiar because that's what you're used to seeing on a container of motor oil. However on motor oil which is listed like 5w30, '5w' stands for '5 winter' so this is where some of the confusion arises.

In addition, fork oil weights aren't measured using the SAE scale. Instead, they rely on the Saybolt Seconds Universal (SSU), a standard used for hydraulic applications. The SSU uses a similar measurement standard to the one used to determine a cSt value, but oil grades are based on a more sensitive scale of viscosity calibration.

How does the Saybolt Scale (SSU) Work?

The thickness of hydraulic and fork oils are listed as the Saybolt Seconds Universal at 100 degrees C/viscosity index. For example, if the numbers listed on the bottle read as 75/150, that means the oil's SSU at 100º C is 75. The flow of the oil is then measured at 40º C. The second number (150) denotes the difference in flow between the two temps, aka the viscosity index (VI).

The Viscosity Index (VI) measures the stability of fork oil between 40 and 100 degrees Celsius. The higher the VI rating, the more stable the weight of the oil remains when it gets hot - in other words a high VI is important for your fork to perform consistently as heat builds up. Again, though, fork/suspension oil weight is also not measured using the SSU scale. Yes, this is confusing, and that's the reason why WPL would love to see centistokes used across brands, because cSt is a standardized measurement.

That's a lot of indexes and scales, but the important takeaway here is that because of the variables of SSU/VI vs. SAE scales, using a 'wt' scale doesn't give an accurate measurement of how a fork or hydraulic oil will behave. Effectively, one brand's 7wt oil could be lighter than another brand's 5wt, and any two different 5wt oils are not alike. This means that if you - or your shop mechanics - use a different brand of oil to service your fork, or a higher or lower viscosity, it could lead to different results.

Why should you care?

Because with standardized suspension oil measurements, it'll be easier to choose what works well for your riding style and conditions, and make adjustments according to changing needs. Without it, you'll be guessing.

We're used to choosing suspension oil like motor oil - using measurements like 5wt or 10 wt - but those values are not standardized across brands. That's why WPL also uses centistokes (cSt) to measure the Viscosity Index of their suspension products. They also use 'wt' but those values are only relevant when compared to each other, not when used vs. another brand's ratings.

Suspension oil has three main roles

The three roles of suspension oil are to provide damping, dissipate heat, and provide thermal and chemical stability to prevent degradation over time to the oil itself or the components it comes in contact with.

Regarding the prevention of degradation, a key term to be familiar with is lubricity, which indicates a substance's ability to reduce friction. A suspension oil's lubricity is therefore important from the perspective of preventing premature wear and providing a low coefficient of friction. A substance's lubricity can't be directly measured, rather it is quantified within a specific system and environment based on how much wear a surface undergoes in a given amount of time. Suffice to say that a lubricious (ie. having a low co-efficient of friction) suspension oil is critical to minimize wear, and will also create a molecular protective boundary between parts (we also discussed these boundaries and hydrodynamic states in the Two Minute Expert article about lubes).

Suspension oils need to be optimized for seal & rubber compatibility

Typical suspension oils are petroleum products. Like with most chain lubes, the reasons for this vary from low production cost (and high margins), good performance across different conditions, and availability of materials to work with - but all this comes at the expense of harm done to the environment during the extraction and refinement processes, and disposal challenges.

It's important to make sure a suspension oil fulfills its three main roles (above) but also that it doesn't break down the nitrile rubber seals and components inside your suspension. Some petroleum-based suspension oils aren't nitrile compatible, meaning that over time they will contribute to premature wear of seals and other components, introducing a whole other set of problems.

WPL's suspension oils replace petroleum with natural materials (extracted from a seed) which rely on single digit percentages of additives, and formulated so that the main ingredient does most of the work. There are mineral-based suspension oils, but they generally have higher percentages of additives (up to 20%) and it's important to remember that despite the fact that 'mineral oil' sounds benign, it doesn't mean they're not toxic or harmful to the environment.

It isn't just compromised seals that impact the longevity of your suspension oil. When it changes colour, what you're seeing is oxidation of the additives in the oil - again, a lower percentage of additives can be helpful here. Some of WPL's testing shows competitors' petroleum-based suspension oils evaporated and degraded faster than the all-natural formula they've developed, in addition to showing more oxidation and deposits.

A Final Note on Handling and Disposing of Suspension Oils

By now this may be obvious, but mineral or synthetic oils with toxic additives must be disposed of in the correct way, otherwise they can end up in our ecosystems. Always check with your shop if you're unsure of how to safely dispose of used oils. And of course, regular users of those products should be wearing gloves and avoid inhaling the fumes because they are carcinogenic.

Further reading & sources

https://www.shimrestackor.com/Physics/Fluid_Dynamics/Viscosity/viscosity.htm

https://www.ridereports.ca/2011/09/secret-world-of-fork-oil.html

http://www.peterverdone.com/wiki/index.php?title=Suspension_Fluid

Comments

Mammal

1 year, 7 months ago

When it comes to WPL, I trust the opinion of the fine folks at Suspension Werx, and they won't touch that "cooking oil" with a 10ft pole. More than half of my squishy bits these days are DVO, and being a notable user-serviceable brand, they used to recommend WPL among others. They've since stopped recommending WPL, because it can cause seals to swell, and gum up internals.

Reply

Kenny

1 year, 7 months ago

First I'd heard anything negative about them - DVO themselves speak very highly of WPL, or at least used to?

Edit - reading comprehension failure. So DVO (Ronnie) actually no longer recommend it?

That kinda sucks. I'm doing a rebuild and damper service on my diamond this weekend and have a cabinet full of WPL.

Reply

Mammal

1 year, 7 months ago

DVO no longer lists it as recommended, like they used to. I'm not sure if that comes from Ronnie or not.

FWIW - DVO New Zealand said that the seal swelling issue was from less than 10% of applications, and suggested that you probably shouldn't worry about it much if you've recently serviced with it.

I've heard about the issue of WPL leaving residue and gumming things up elsewhere previously (SW and others), but that particular info, in this case, came from DVO New Zealand.

Reply

Kenny

1 year, 7 months ago

DVO north america confirmed this morning WPL is still ok...

Reply

Carlos Matutes

1 year, 7 months ago

I’m one of the unlucky 10% (according to DVO NZ) who had issues with swelling at the air piston from using WPL.

When I spoke with DVO a couple of weeks ago, they said they were aware of some issues, suggested installing a new air piston and switching to another fluid, I’m using Maxima 10w until it gets cold.

So far the fork is waaaay less sticky. I only have a couple of rides on it, but the traction is noticeably better.

Reply

Mammal

1 year, 7 months ago

For DVO service, I've been using Motul 2.5W for dampers and Fox Gold for lowers. 3 years in, and all is well.

Isaac Marangoni

1 year, 6 months ago

DVO does not recommend WPL nor does it recommend Maxima oil for the same reasons of nitrile rubber swelling.

However, WPL has proven that our oil causes less swelling and softening than both Maxima and Fox OEM oil and discussing with DVO to amend this statement.

Residue and gumming is not a valid allegation either and there is no data to back this up. I would ask DVO NZ for proof of this.

Reply

Isaac Marangoni

1 year, 6 months ago

Hi Kenny, this discussion is ongoing with DVO as we had started trials of our oil with a DVO employee who was dropped and no longer works with the team. Since then, there was no conclusion on the trials which we pushed very hard for. Your suspension is not at risk. Thanks.

Reply

fartymarty

1 year, 7 months ago

Mammal - I did the same over here. Called up TF Tuned, asked what oil they recommend for Öhlins forks and bought some. Being an Öhlins sales and service centre I trust them. Bouncy bits are too expensive to risk messing it up.

Reply

Flagrant_Mechanic

5 months, 2 weeks ago

Suspension is expensive, but, well, a piston seal is pretty inexpensive and we routinely change them anyway at regular maintenance intervals. It's not like if an incompatibility pops up the fork is ruined.

Reply

Isaac Marangoni

1 year, 6 months ago

I am Isaac a co-founder of WPL BIKE.

Suspension Werx only uses warranty approved oil such as Maxima for RockShox and Motorex for Fox because they are sticking to manufacturer recommendations, but WPL is far from being a "cooking oil" a defamatory term that is not backed up by any valid data.

WPL has performed all sorts of testing to prove the efficacy and safety of the oil on nitrile rubber seals and its effect is less destructive than both Fox and and Maxima oils.

DVO also does not recommend Maxima oil for the same stated reasons of being destructive on nitrile rubber seals and yet this is not regarded as "cooking oil".

WPL has also gone through multiple reformulations since the days of Suspension Werx use of the product which was back in 2017.

The statements from DVO NZ on WPL seal swelling are invalidated and not backed up by any solid data. You can ask them to provide this data if you are curious and will see that it is non-existent.

There are many hurdles that we as a company need to jump over in order to bring sustainable chemical products to a market that is riddled with toxic waste, and human bias can have a large effect on product evaluation.

We will stick to empirical and scientific data collection and testing procedures and are in discussion with DVO at the moment to amend this false perception that was created by one employee who no longer works with the DVO team.

Reply

Isaac Marangoni

1 year, 6 months ago

Hi Mammal, can you please ask SWerx when is the last time they used WPL oil? I would suspect it was back in 2016 or 2017.

Our oils are far from being "cooking oils" and we have tackled every major hurdle in developing a functional technical fluid for these applications, and published it to our blog on wplbike.com.

Bio-based oils are now used in many industries including metalworking fluids, hydraulic fluids, heavy machinery, crank case fluids, and have been used in automotive engines before. It is now mandated in Canada to use bio-based fluids in protected areas for heavy machinery performing maintenance work on pipelines and projects such as this. CAT sells bio-based oil for their machines as well.

Late adopters will always have difficulty overcoming bias and you need to ask for some basic evidence before believing a comment such as "cooking oil."

Reply

kcy4130

1 year, 7 months ago

A bit off topic, but I really wish forks had a lowers drain plug and a port to add fresh oil. Like changing oil in a car, it'd be such a time saver.

Reply

Mammal

1 year, 7 months ago

You can remove some bleeder valves and inject some fresh oil in there. But make sure you keep track of how much was in there in the first place, how much you add, and how many times you've done it. Don't want to add too much volume.

That said, a lowers service should definitely include cleaning out the sludge and built up crap, and a drain/fill won't accomplish that. I can see that being a quality department nightmare.

Reply

kcy4130

1 year, 7 months ago

Yeah, it wouldn't completely replace a full lowers service, but perhaps it'd increase the duration between lowers by a factor of three or four. If it meant that lowers were only needed as often as a full damper rebuild, that'd be ideal. There'd be less sludge build up cause one could change it more often.

Reply

Isaac Marangoni

1 year, 6 months ago

This built up "sludge and crap" from regular suspension oils is oxidized polymer additives and base mineral fluid that is the result of heat and shear damaging the compounds present in technical fluids like suspension oil. This is why it is important to stick to regular service intervals for all fluids, however WPL has proven a higher Oxidative Stability Index rating than Maxima fluids using standardized scientific equipment and published it on our website.

Reply

earle.b

1 year, 7 months ago

The Totem had this.

https://ep1.pinkbike.org/p4pb1998671/p4pb1998671.jpg

Reply

Mammal

1 year, 7 months ago

That's wild! I had no idea the totem had those.

Reply

Perry Schebel

1 year, 7 months ago

i actually have a totem, and never used those. such a chonky fork.

Reply

mrbrett

1 year, 7 months ago

This comment has been removed.

JSW07

1 year, 7 months ago

I have to be honest (although I will admit that I'm not the sharpest knife in the drawer sometimes) that after reading this article I am more confused about suspension oil than before.

This is why I will stick to what is recommended by the manufacturer as there is no question as to wether or not it's correct or will work.

Reply

Isaac Marangoni

1 year, 6 months ago

Suspension oil is admittedly an extremely technical product and difficult to understand.

Reply

Flagrant_Mechanic

5 months, 2 weeks ago

JSW07-- I'm happy about your confidence. But big suspension mfrs recommend the fluids they get oil companies to put the company logo on-- it's product that adds to their sales. On the plus side, at least it's a known quantity and they'll eat problems for gear still under warranty, which is a good argument for sticking to what they recommend. We've seen, though, companies quietly retire or reformulate their branded oils. Lowers oil, for example, wasn't always "20wt", and heavy magic piston fluids seem to be going out of style in favour of lighter oils. Some respected companies don't even believe in oils except for dampers; they prefer grease.

Aside from this mysterious business with DVO piston seals and bio-oil, which may or may not actually be a thing, DVO is kind of a breath of fresh air. They'll sell you a "house" oil they've had consistent results with, but they're fine with a list of brands they're happy to send you, that notably doesn't include Maxima or the Rockshox oils made by same.

Reply

danithemechanic

1 year, 7 months ago

Thanks Pete, this article comes just in time since lately i've been wondering about the change in viscosity related to the change in temperature.

Since i've been clocking laps on the same downhill track at my local bike park this year, i've developed quite a feeling for setting up my suspensions and i noticed, things change if i get them hotter. If i don't have a break somewhere midway and ride more continuosly i can feel my setup changing.

Hence i was wondering, how the world cup mechanics deal with heat affecting oil viscosity in a race run? My idea was either to setup the suspension stiffer since it will loosen up midway or set it when the suspension is hot already.

Either way i'll end up with a worse than optimal setup on half of the track.

Reply

fartymarty

1 year, 7 months ago

Dani - another variable to throw in the mix is tyre pressure which can change with altitude and temperature over the length of a run. I've noticed this on night rides when the temp drops from the start to finish of the ride.

Reply

danithemechanic

1 year, 7 months ago

Sure, but that's a variable you can control that doesn't change too much once set.

Check it on top before your run and you're pretty much set, having your rebound way faster because your damper oil has the viscosity of water mid run is a bit more complicated to sort in the start hut.

Reply

mrbrett

1 year, 7 months ago

I know on a 4x4 you make adjustment notes for a shock when it's at operating temp. But in one of those there's more oil and a lot more metal, so it takes much longer than a bike fork or shock that comparatively warms and cools fast. I'd guess the telemetry gear you see on WC DH bikes incorporate ambient and suspension temp sensors to help with this.

Add to that it's generally cooler at the top of the mountain (where the racers are hanging out waiting for their slot).

Reply

kcy4130

1 year, 7 months ago

Everyone says that downhill is the F1 of mtb. So just like in F1 where they externally warm engine oil, tires, and probably some other things before taking to the track, for optimal suspension setup you'll need to put electric heat blankets on shock/fork to warm them before starting a run.

Reply

Pete Roggeman

1 year, 7 months ago

These are good questions and I do think it would be great to get some answers. Maybe we can get Jordie or someone similarly qualified to answer a few questions on the topic.

Reply

danithemechanic

1 year, 7 months ago

I was working at the Trophy of Nations all week i should have asked him directly !

Reply

Isaac Marangoni

1 year, 6 months ago

Hi Dani, the change in viscosity with temperature is measured by a metric called Viscosity Index. All fluids will lower in viscosity if temperature rises which is why VI improving compounds are used to counter-act this affect, because consistency of suspension performance is necessary in a sporting application. We've published our VI data on our blog at wplbike.com.

Reply

Sandy James Oates

1 year, 7 months ago

Always used Maxima products with great results.

Reply

Isaac Marangoni

1 year, 6 months ago

DVO does not recommend Maxima due to "damage to nitrile seals"

Reply

Jerry Willows

1 year, 7 months ago

use what the manufacturers recommend....

Reply

JSW07

1 year, 7 months ago

Yeah agreed, I'm not sure why anybody would use anything but what the manufacturer recommends. Dispose of the products properly and everyone should be happy.

Reply

Skooks

1 year, 7 months ago

Nailed it right there. Using the Manufacturer's recommended product seems like the best practice.

Reply

kcy4130

1 year, 7 months ago

Agreed. Eco friendly chain lube? Sure, I'll try that, it's low risk: worst case is that it doesn't work and I wash it off go back to my usual chain lube. Suspension oil... If that doesn't work as desired or causes issues that's a lot of work or money to fix.

Reply

Cee Cee

1 year, 7 months ago

Chug it, Pete. PVD Wiki!

Reply

Pete Roggeman

1 year, 7 months ago

I'm not a fan of a lot of what he's had to say, but his wiki on this topic was clear and well-researched.

Reply

[email protected]

1 year, 7 months ago

This comment has been removed.

eshew

1 year, 7 months ago

My favorite CST @ 40 chart from Peter Verdone. Great for tweaking just a little bit or for matching a tough to find oil.

https://www.peterverdone.com/wiki/index.php?title=Suspension_Fluid#:~:text=attempt%20to%20change%20any%20settings%20in%20the%20suspension%20or%20make

Reply

Flagrant_Mechanic

5 months, 2 weeks ago

Have to say I'm kinda puzzled by some of the MTB world's reaction to bio-based lubes like WPL. For people that like flying through the air, think nothing of crashing occasionally, and accept busted components and even frames as going with the territory, some of us sure are superstitious when it comes to lube. As a group, I like to think of riders as some of the most "think for yourself" kind of people, and a lot are incredibly technically adept. That's why it seems weird we'd accept rumour without following up the science, and it's not like dropping sample seals in oils to see what happens requires rocket science.

I'm not connected to any bike gear or lube company, but have used WPL for just about everything over a number of years in forks, shocks, and bearings both wheel and linkage. None of the seal samples I've test-soaked in bio-based oils has ever swelled or showed issues-- surprising really as you expect to see at least a few issues no matter what kind of lube. No suspension or bearing issues that I could document as a result of bio-oil.

Far as "sludge" goes, maybe I've been lucky but so far cracking open a fork or damper full of WPL has been a lot more pleasant and easy than petro-oil treated ones, many of which have been positively vile inside. Guess anything gets dirty if you avoid maintenance long enough.

But I just did brakes on the car, and the (petro-based) brake lube from a large trusted chemical company sold by mainstream retailers caused the caliper slider rubber to swell and seize. Wasn't just occasional issues-- a mechanic I asked has changed routines to either toss the rubber or replace pins on brakes that come in like that. Checked back and found the maker had quietly reformulated and now sells the new stuff in the same packaging as the old, labeled as "improved". No dark rumours-- people still buy, sell, and use the stuff-- you can document this effect at close to 100%, not the occasional rare event, but nobody says "what did you expect, it's a PETRO oil, made out of compressed decayed sea life!"

Any lube needs to be tested, and if the world is still riding in 50 years it's likely to be with veggie lubes as it was in the beginning (Castrol racing oils were castor bean oil blends; many WW1 fighter planes used 100% veggie lube).

Maybe we should pick oils based on evidence, not rumours?

Reply

Please log in to leave a comment.