Preview

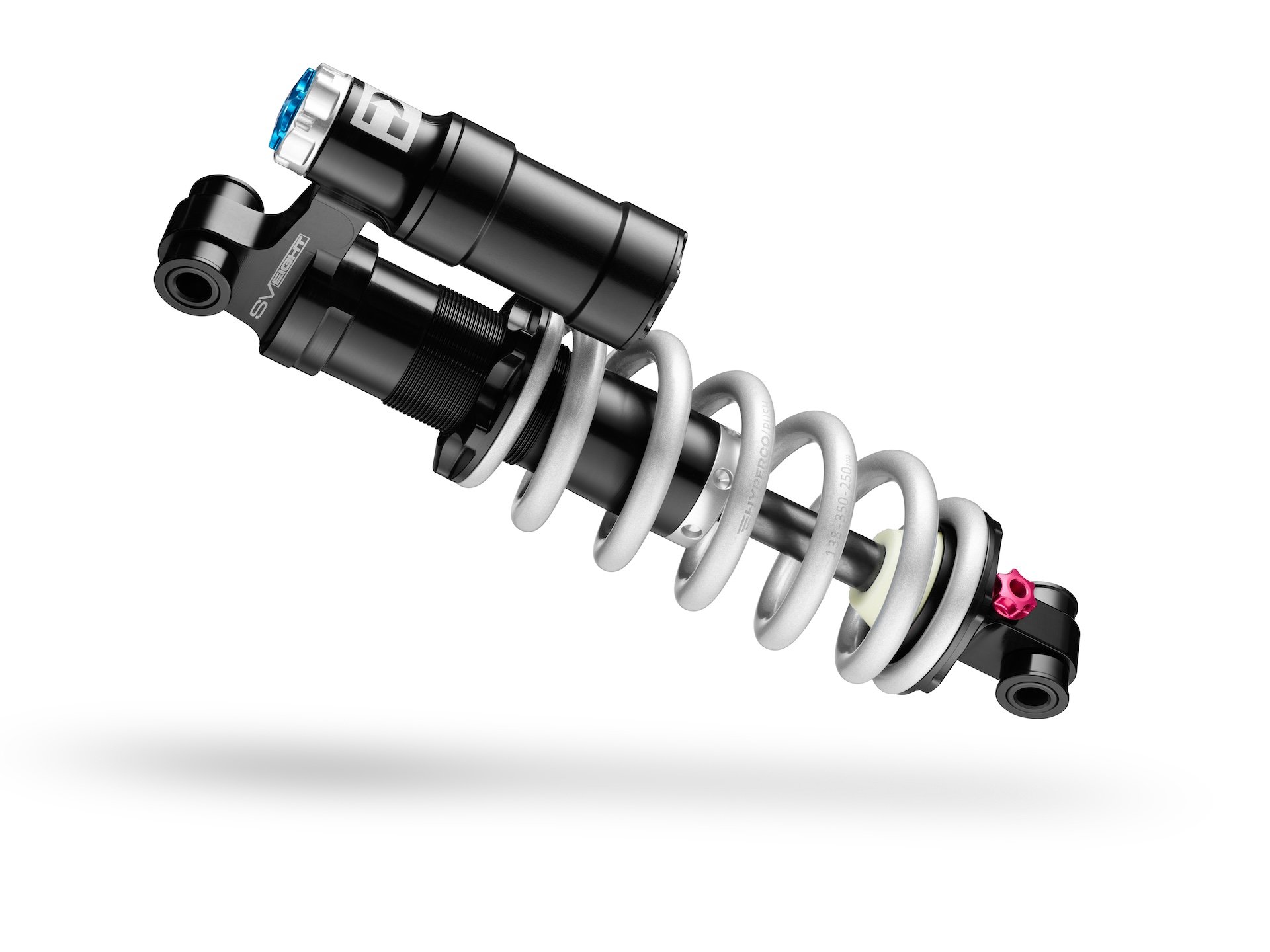

PUSH SV Eight

This Man Wants You To Buy His Shock

Push Industries have built a brand defined by quality and service. Starting out as a suspension tuning shop, getting it right by the customer was the main priority. From tuning, Push moved into suspension componentry with coil spring conversion kits to bolster the tuning business, before birthing the ElevenSix shock in 2015.

Making the leap from suspension tuning shop to full-blown manufacturing facility was a huge move, but the core tenets remained in place; attention to detail, quality of manufacture, and dedicated customer service. The ElevenSix is entirely made in-house in Loveland, Colorado - from design, to prototyping, testing, iteration after iteration of R&D, and finally to machining each and every part on a bank of insanely sophisticated and expensive DMG Mori mills, then assembling each of those parts, one shock at a time, to exact specification and tune per customer. It's a very expensive shock. There is also nothing else like it on the market. And it is only available for a limited number of bikes.

And so we get to the new kid on the block, the fresh out of the mill SV Eight.

Low key looks, off the rack aftermarket goodness. Available in two tunes, four lengths, with adjustable high speed compression, low speed compression, and rebound damping. This is PUSH's shock for the masses.

This Shock Is Not Like His Other Shock

The SV Eight signals PUSH moving from one-off, bespoke custom manufacturing into something resembling mass production. Or maybe, more accurately, batch production. With the ElevenSix, each shock is made to order, one at a time, with one tech gathering the parts then assembling the shock to a tune specific to a particular bike and customer. It is labor intensive and time consuming, and the price of the ElevenSix represents that effort. With the SV Eight, PUSH is making shocks in batches, with preset tunes, to fit a much wider range of bikes for a customer who is looking to upgrade his or her stock suspension but maybe doesn't have the budget or the correct bike, or the ultra-discerning suspension performance demands, that are served by the ElevenSix. The SV Eight is a simpler shock than the ElevenSix, but is still very much an upmarket offering.

"SV" denotes "single valve" and this, along with the batch production process, is what differentiates it from the dual damping circuitry of the ElevenSix. Instead of a pair of switchable separate compression damping circuits, the SV Eight gets it done the old fashioned way like most of the other shocks on the market. Compression damping offers high and low speed adjustment at the end of the piggyback reservoir, and there is a single rebound adjuster at the other end of the shock. The IFP runs at a relatively low 85psi, there's a hydraulic bottom out piston, a Melonite QPQ treated steel shock shaft, the shock is filled with Motorex oil, and, like everything else PUSH makes, the SV Eight is designed, prototyped, tested, manufactured and assembled entirely in house in Loveland, Colorado.

It is available in four lengths: 185x50-55mm trunnion, 205x60-65mm trunnion, 210x50-55mm standard eyelet, and 230x60-65mm standard eyelet. The varying stroke lengths for each shock are achieved by 2.5 or 5mm travel adjustment chips that mount up under the conical bumper at the top of the shock shaft. Each shock length is available in either an "A" or "B" tune; "A" tune covers spring rates from 300 to 500 lb/in, and "B" tune is tailored for 525 to 700lb/in springs.

There is no "climb lever" or switchable compression damping platform on the SV Eight, and PUSH claims that pedal bob and rider induced feedback is handled by its 3-port bridged piston design. When I asked what that actually means, Darren Murphy, founder and CEO of PUSH, said; "The bridged piston is a unique main damping piston and damping characteristic that is balanced with the compression base valve located in the head assembly of the shock. The compression damping characteristic, combined with our low pressure nitrogen chamber, allow us to create a shock that rides with good stability when you’re pedaling down the trail, but can quickly react when bumps are thrown at the rear wheel."

I, being an idiot, still don't know what exactly that means. Also, being an idiot, I forgot to take a picture of the piston when I was snooping around the factory...

The innards are notably different than the ElevenSix, but the really big change that the SV Eight signals is seen right here - batch assembly. This required an entirely new manufacturing-production learning curve, but developing the ability to step away from painstaking one-by-one bespoke builds and assemble shocks dozens at a time is how the price was able to get cut roughly in half compared to the ElevenSix.

Riding The SV Eight

Since I happened to be snooping around the PUSH facility, and since I had a brand new bike with me, Darren hijacked my rig and gave me the nickel tour of the factory while the boys swapped a new SV Eight in where a similarly new Fox DHX2 had been. Then they kicked me out before I could ask for a new fork as well, and set me free to roam the frozen wastelands of Colorado. I Finally got to ride the new shock in St George, Utah, managed to get some rough bracketing done there, then made it back to Santa Cruz for a couple more rides where I think I am zeroed in where I want to be for now. That's a longwinded way of saying I only have about 8 hours on the shock so far, and this is best looked at as a "first impressions" kind of thing rather than a thorough long term grind.

I currently weigh 190lbs dressed to ride (Damnit! I was 180 two months ago. Goes to show what a diet of gas station food and stress will do to a boy. No wonder my clothes don't fit anymore), and my Starling Murmur is a 150mm travel single pivot that uses a 230x60mm shock. The initial spring rate calculations suggested a 450lb/in spring, which matches what the Fox calculator spat out for the same setup with the DHX2. Bouncing it around the parking lot led us to mount a 475lb/in spring, and Darren threw a 500lb/in Hypercoil spring in as I drove away, just in case I gained any more weight.

With one turn of preload on the spring, sag was 18mm - right about 30%. Spring aside, I went with the stock suggested settings for the first ride. There are 25 clicks of low speed compression damping adjustment, 25 clicks of high speed compression damping adjustment, and 18 clicks of low speed rebound damping adjustment available. The "Out Of The Box" setting is with the clickers smack dab in the middle of the adjustment range; 12 clicks out from fully closed on each of the compression knobs, and 9 out on the rebound.

Initial impressions on the combined chunk to loose rock riding in St George were of a buttery plush initial response that felt like it was maybe a tad eager to move through the mid stroke but still resisted bottoming with impressive resolve. There was definitely some light pedal bob when spinning at low effort on flat ground, but once I started digging in on proper climbs things settled down. I still would like a climb switch, because I am aboard a simple suspension design that doesn't have any linkage or floating instant center magic to help with climbing. That said, I was very impressed with the tractability and responsiveness of the shock when pedaling uphill.

Back in Santa Cruz, I started targeting the mid-stroke behavior, and ended up adding a few clicks to both the low and high speed compression settings after experimenting with running them each fully open then fully closed, ultimately ending up at 10 clicks out on the low speed compression and 7 out on the high speed. Rebound is at 5 out. This gave me what feels like the most pedal-friendly all-round setup that absolutely devours wheel craters and g-outs and stays beautifully composed when plowing rock gardens. There was some small amount of that silky smooth small bump compliance sacrificed but it is still ridiculously plush for a single pivot. If I was really smashing deep into the travel on a regular basis, I might opt to speed up the rebound a hair, since all the cool kids run fast rebound these days, but for this spring rate, the current setting feels good most everywhere else - doesn't pack down in the fast stuff, doesn't pogo in the slow stuff.

There's something to be said for understated graphics...

"but these ones go to twenty five..."

Have you ever noticed how the rebound adjusters never really get to show off like the compression clickers?

The shocks ain't cheap, and the springs cost extra. But they ain't just any springs. Hyperco springs add a double extra fancy frosting on the SV Eight cake...

According to Cam, I never take enough pics of me riding. This, in spite of my well chronicled "old man looking stiff and scared" riding style. Trust me, the bike looks way better without me on it.

Is it worth it?

Hell, I'm obviously not qualified to answer that. I just forked over a couple grand for a filet brazed steel single pivot frame. Obviously my priorities are not well aligned with the meat of the market.

At 865 USD, the SV Eight is a downright bargain compared to an ElevenSix. But the ElevenSix is so over the top in every sense that it is not fair to try and pull that comparison. The SV Eight is roughly TWICE as expensive as a Fox DHX2 or a RockShox Super Deluxe Coil Ultimate, once you factor in the extra money you need to spend outfitting the SV Eight with a spring and mounting hardware. Both the DHX2 and Super Deluxe Coil Ultimate are very respectable shocks. Is the SV Eight twice as good as them?

No.

It's good. It's really good. But I'm not convinced it is twice as good. I prefer the way the SV Eight works to the Fox that was on there, but to be fair, I hadn't spent enough time dialing the DHX2 in to really get it singing. However, the combination of tractable plushness and mid-stroke poise that I was able to find in relatively short order with the SV Eight impressed me. It was real easy to get to know, and I am really looking forward to geeking out on bracket runs over the next few weeks to see where this goes.

There's more to it than a straight up plushness per dollar ratio, though. And since I AM the kind of guy who will throw money at bikes made out of steel, I can also really get behind the idea of something that is made entirely in one place in Colorado, soup to nuts as they say, by people who live, eat, sleep and dream mountain biking, and who have a reputation for customer service that goes well beyond what anyone else is doing in this arena. That matters more and more to me the longer I stick around on this planet.

Who wouldn't want to buy a shock from an outfit that uses an ElevenSix for a beer tap?

Knowing that those DMG Mori mills need someone to help pay for their cutting oil habit, knowing the people who work at PUSH, knowing that if I completely hamfist myself into a corner turning knobs the wrong way someone will answer the phone at the other end and help me unbollox myself, that makes the SV Eight worth every penny to me.

But, as already mentioned, repeatedly, my motivations are not rational. Maybe yours aren't either.

Comments

Timer

4 months, 3 weeks ago

It seems a bit weird to me that Push doesn’t include any form of rider specific customisation with this shock.

I’m thinking that if one were to send a DHX2 or Super Deluxe Coil for custom tuning, one might end up with a shock that is cheaper and at least as good as the SV Eight.

Reply

Heinous

4 months, 3 weeks ago

On return from tuning, maybe - I back to back tested a Push with a Tractive tuned RS unit and they were close initially.

I’ve found the quality of the Push shocks so good, and the durability so good, that it pays dividends at the times other shock have developed issues or blown.

Each time I’ve put a push unit in a bike there’s been an aha! moment where I’ve though ‘oh, this is how the person who laboured over designing this bike thought it was going to ride, until a PM put a shitty shock in it’.

Reply

Mike Ferrentino

4 months, 3 weeks ago

Since I have so few hours on this shock personally, I couldn't speak to the durability aspect. But everyone I know who has spent any time tuning working on shocks mirrors your sentiment about build quality and durability of PUSH components - they sweat the details and make stuff that holds up.

Reply

Timer

4 months, 3 weeks ago

Good point, if durability and reliability are superior to standard shocks that would certainly be an advantage for the Push.

Reply

Vik Banerjee

4 months, 3 weeks ago

That's what I did. My Super Deluxe Coil is amazing post-vacation at Vorsprung. When you factor in the cost for a normal full service getting the shock customized was a bargain. I'd 100% rather have a customized "regular" shock than a premium production shock.

Reply

Heinous

4 months, 3 weeks ago

That was my thought a few years back, and there’s no doubt a Vorsprung tuned shock is a thing of beauty.

I only ended up with a Push unit as it was when Trunnion became a thing and there were huge shortages on them. The shop supplying me a frame offered me a push at a massive discount and I’ve not really been able to go back.

Reply

the prophet

4 months, 3 weeks ago

Not changing the HBO components when reducing the stroke makes for very limited HBO functionality.

An HBO that engages in the last 10mm of stroke is rendered pretty ineffective when the stroke is reduced by 5mm and there is also a large (captured) bottom out bumper present.

But having HBO in the description will sell more units. :)

Reply

Justin White

4 months, 3 weeks ago

That might be part of the reason they're not supporting a 7.5mm stroke reduction like many shocks are lately: 47.5 and 57.5 strokes are possible on pretty much all mass-market shocks, with the same style of stroke limiting spacers, including some with HBO. Perhaps Push decided that having only 2mm of HBO wasn't worth it and just left out those less common* stroke lengths.

Meanwhile, RockShox is totally fine with saying "HBO for 20% of travel", even though that's probably only accurate for the longest stroke for a given shock body, and the maximally reduced stroke option will only be getting like 6% (2.5mm) of HBO.

It is slightly unnerving that Push also only mentions the "15%", without noting you'll be getting less HBO with any travel reduction, even though the possible reduction in HBO is less overall than others.

*(They seem to be most often used for artificially-restricted-travel builds. Like the Score 2030 has a frame that can handle a 52.5mm stroke for 130mm travel, but all builds come with a shock limited to 47.5 stroke for 120mm travel (for marketing?). Similar with the Transition Scout: stock build is 57.5 stroke for 140mm, but a 62.5 stroke for 150mm is officially supported.)

**(On another note, I truly don't understand that limiting concept. Same frame, same weight, same everything: Why wouldn't you take all the possible extra travel at the bottom? The extra travel doesn't mean you automatically need to increase sag, and the bike manufacturer can easily mitigate this though by specifying their intended sag in absolute stroke distance instead of percentage.)

Reply

Reilly Hohman

4 months, 3 weeks ago

Not sure about the Vivid, but the Super Delixe Coil has different bottom posts for different length strokes so that the HBO still usable and fully effective.

Reply

Dave Smith

4 months, 3 weeks ago

That Murmur is a real beaut and I bet it howls with that Push.

Sidenote: I'm so happy that we live in an age where the merest mention of a single pivot doesn't have to be immediately followed by the words brake jack.

Reply

Morgan Heater

4 months, 3 weeks ago

Andrew Major prefers to expound upon the cult of starling and inferior braking charateristics, rather than uttering the plebian, "brake jack".

Reply

Andrew Major

4 months, 3 weeks ago

That Andrew Major guy is a dipshit in general, but in this specific case, he’s actually on the record as loving simple single pivot bikes. I even have it on good authority that if he could choose any one full suspension bike to review it would be to frame-only-review a mullet Orange Alpine Evo. In ‘Purple Reign,’ of course.

The Starling Fallacy doesn’t have anything to do with suspension design, it’s about people who buy bikes.

It would be awesome to see more companies using/selling* simple single pivots for their more budget options, like Santa Cruz previously did.

*being able to sell.

Reply

Perry Schebel

4 months, 3 weeks ago

in my fantasy alternate reality, SC would revive the super-8 as a modern, metal, no frills, bang-for-the-buck single pivot all round thrasher. probably with beer can swingarm integration.

Reply

Fat_Tony_NJ

4 months, 3 weeks ago

I sure miss the old Heckler.

Reply

Mammal

4 months, 3 weeks ago

I rode a 2003 SC Heckler for 9 continuous, hard-ass years. It never batted an eyelash.

Reply

Jerry Willows

4 months, 3 weeks ago

how much more does it cost to have an extra pivot? So much more tuneability with a "Horst" link it's really a no brainer, especially with no patent issues.

Reply

Andrew Major

4 months, 3 weeks ago

There are at least six extra bearings between a simple single pivot frame and a Horst link or linkage-driven single pivot frame.

Thats significantly more QC/QA on bearing journals, small concentrated welds (not a lot of room for a Horst pivot between the chainstay and dropout), etc. All things being equal (where/how it’s made) a simple single pivot frame will be less expensive to design and manufacture and maintain.

Bearings aren’t free, nor is their installation, and for every company like Santa Cruz and Specialized that have designed (cost again) shielding such that bearings last multiple seasons for most riders, there are still examples of frames that require replacements at least yearly.

So yes, if the goal is to make the best full suspension bike for the least money, simple single pivots would have their place.

Again, if riders outside of a small niche (Orange, Starling, various small & custom builders) were interested in buying them. Santa Cruz tried to bring back the Bullet and Heckler (before making them BroPeds). Demand is not there.

Reply

Jerry Willows

4 months, 3 weeks ago

you still didn't answer my question though... I bet it costs $5/$10 per frame, less than a th(d)umb shifter.

Andrew Major

4 months, 3 weeks ago

$5/$6 per frame for the extra design time/experience, welding, machining (linkage that drives shock and pivot hardware), and QC/QA. I’m confident your estimate on the cost difference is very low no matter what country you’re getting those frames made in. No matter the material and quality of bicycles you’re making.

I mean, what do I know right? Ask your friends at Specialized for just the cost of the shock driving linkage assembly (rocker & hardware).

Heinous

4 months, 3 weeks ago

Plus the more complex the higher the scrap rate, so factor in the cost of those frames too. Then the cost of those that are missed, shipped and sold ($$$), then warrantied.

Justin White

4 months, 3 weeks ago

"and for every company like X that do Y, there are still examples Z"

That goes both ways. Just because some people don't do something right doesn't make that thing always bad . For Every Starling with strong, aligned, well-protected single-pivot bearings and shock-mounts, there are going to be some that are weak, mis-aligned, and not well-sealed.

Don't forget that with a direct-drive single-pivot, either the shock mounts also need to be similarly well-aligned and strong if the shock is a stressed member, or the main single-pivot needs to be super strong and perfectly aligned properly carry the entire load of the rear end by itself. That adds cost. Perhaps not quite the cost of 3 more pivots directly, but since those extra pivots also add value via bringing flexibility to the design, their effective cost is amortized into the whole system. One could argue that Starling should be spending significantly more per pivot, so it's not apples to apples just counting pivots and bearings.

fartymarty

4 months, 3 weeks ago

Mmmmmmurmur.

Just the sight of it makes me want to get mine out of winter retirement.

Reply

Mike Ferrentino

4 months, 3 weeks ago

Single pivots are a target rich environment for criticism here in the age of sophisticated multi-link kinematics, although a slightly high forward one still does a surprisingly good job even if lacking in the broad spectrum squishability. But brake jack, sheesh, I never really understood it. I mean, yeah, it happens, but people preoccupied with it always seemed kinda princess and the pea given all the other shit that happens when braking on rough terrain...

Reply

Dave Smith

4 months, 3 weeks ago

Perry loved that Murmur. I never heard him whinge about the kinematics on any ride and he shred her majesty's fuck out of it for the review. In fact, I think there was an exponential degree of separation anxiety after he finally returned it to its rightful owner. Nice bike.

Reply

Perry Schebel

4 months, 3 weeks ago

yeah, it's a fabulous combination of well sorted geometry, that steel je ne sais quoi (compliance, i guess), and a healthy dose of anachronism (which really pushes my buttons).

if i had any criticism, i generally prefer more progression (ie, afforded by linkages), though somewhat tunable using an air shock stuffed with volume reducers. i imagine it's a bit of a balancing act with a coil (suppleness / grip vs support).

really neat bikes, regardless.

Reply

Cr4w

4 months, 3 weeks ago

I love that in a time of such complicated bikes (like HPIs) that a modest steel single pivot can stand with the best of them.

Reply

Perry Schebel

4 months, 3 weeks ago

jaded me questions the net benefit of hp's (for the average consumer); leading me to surmise that it's more driven by marketing (as the hot new thing) than raw performance. (side-eye glance at trek slash).

Mike Ferrentino

4 months, 3 weeks ago

I am surprised that the Starling works as well as it does with a coil, given the linear or maybe even falling rate nature of the design. I also say it "works so well" within my own limited parameters of riding - meaning I don't smash jump lines or really put the suspension to the same test that really fast ballsy riders do. And I suspect it would bottom out a little too easy for those riders.

Reply

Lu Kz

4 months, 3 weeks ago

There's something special about a steel bike being ridden fast by a dude who looks like he could be on stage with a Swedish death metal band.

Reply

Justin White

4 months, 3 weeks ago

"given all the other shit that happens when braking on rough terrain"

I think that's the whole point. Given all the other shit, having the rear wheel gain or lose traction intermittently as part of a negative feedback loop with rear braking force is not ideal. Especially the way unmitigated single-pivot anti-rise acts: grab the brakes, rear has traction braking force is high, anti-rise happens and suspension compresses, weight shift forward happens anyway because that's part of braking, rear wheel unweights, rear wheel slips, anti-rise force reduces, suspension extends, rear wheel gets traction and good braking force, go back to step 3.

Given all the other shit happening when braking hard in situations of large jank-factor and questionable traction-factor, I think most riders would rather have a more consistent braking feel, and more useful feedback about traction, rather than the cycle of traction/anti-rise/slip/rise.

Considering the many other suspension designs that can mitigate this to varying extents, that have been proven viable in various materials and configurations, the only decent argument nowadays is the [potentially] reduced maintenance from fewer pivots. Though at the same time, it also means those pivots are going to be seeing much more of the load, so they're going to have to be extra strong and extra well protected, which can add weight/complexity back into it, or might translate to more frequent maintenance windows.

Reply

BarryW

4 months, 3 weeks ago

While you make valid points, literally all motorcycles use single pivot suspension and no one cares. It's simple, brakes work just fine.

Reply

Justin White

4 months, 3 weeks ago

All motorcycles weight significantly more than a mountain bike, and good motorcycles use significantly more complex linkages to control the leverage rate and mitigate some of the deficits of the SP. Very different characteristics to a direct-drive single pivot, and there are also a whole bunch more pivots in that linkage. Plus the motor, and it's not even close to apple-to-apples. Also, a moto's single-pivot is not even close to the same placement as a mountain bike, and actually could mitigate some of the anti-rise effects due do being [relatively] so much lower.

Reply

JT

4 months, 3 weeks ago

Upvoting because I remember when QR fork drops would crack due to disc torque and dropout slot orientation. Had a pal tell me caliper orientation doesn't matter, but I couldn't accept his reasoning. To me it looks like there's a change in inertia in the system and the direction of that change matters as to how a bike will squat with the relation between the line between main pivot and axle and the line through the center of the caliper towards the main pivot. But, I'm ignorant here. But the rise of chainstay- chainstay-ish mounted calipers seems to confirm my thinking.

Justin White

4 months, 3 weeks ago

@JT, the caliper orientation doesn't matter because the torque it's applying is always around the axle. You could move the caliper to the front of the fork and it would still want to push the axle out of those old dropouts, because the rotation it's trying to stop is still around the axle in the same direction. Caliper orientation would have an effect on the caliper mounting points (pushing onto the posts vs pulling off the posts vs shear against an IS mount), but not the torque to the whole system (it's still trying to spin the fork around the axle). Move this to the back, and a brake mounted to the chainstay (only one pivot away from the BB) is always trying to rotate the chainstay around the axle in the same direction that compressing the suspension does, from the viewpoint of the rear axle. A line through the caliper center means nothing, it's all about the connection[s] between the axle, the caliper, and the main pivot.

I don't think there is a " rise of chainstay- chainstay-ish mounted calipers" unless your also seeing a rise in single-pivots, because they are the only designs that use that mounting position. Note that while some mounting locations are on the lower portion of the rear triangle that we could call the chainstay, like perhaps on an Ibis Exie, it's still mounted two pivots away from the BB, hence does not directly rotate the suspension into compression. The "chainstay" from suspension view point is actually the lower link.

Shinook

4 months, 3 weeks ago

I've had my Murmur about a month now, half of which has been spent in a surgical cast, so I don't have a ton of experience yet. I'm coming from several other steel bikes with multipivots, mainly REEBs, but I've also had bigger travel mainline brands from Specialized, SC, etc in recent years. The number of pivot points on my Enduro was enough to make you rage quit the bike and sell it in pieces, but I've done plenty of bearing maintenance (sometimes monthly) and I largely agree that the cost and work is overstated. It's not that hard once you get the tools. I didn't buy it because it's easier to maintain as most bikes are perfectly content to be dunked in mud, ridden, never washed, and still run smooth for close to a year without seized bearings.

That being said, I don't really understand the brake jack complaints. I haven't had a chance to get it on super steep terrain yet, mainly longer mellower grades descents we have in NC, but I've yet to get this "brake jack" feeling people describe. I didn't have the pleasure of riding the old Klein Mantra or other bikes that actively tried to kill you, so maybe I'm just not accustomed to what brake jack feels like, but I've had plenty of sustained braking across rough terrain on this bike and not yet felt like it was an issue. I don't really get a feeling of being flung forward on the bike, the rear seems to retain the same braking traction as most bikes I've had, and it doesn't seem to lock up on square edges, again how some other bikes I've had do with multipivots.

I get that engineering is objective and single pivots will inherently have flaws the same way a poorly designed multipivot bike will, but whatever they are, I haven't identified them yet and I'm usually pretty attentive to those types of things. If anything, I find the linearity of the bike somewhat relieving in a time when it feels like some bikes attempt to be too progressive, making for a harsh ride that tracks poorly. I get that it's easy to find bottom on these bikes, something that I've found in my time getting a feel for the bike, so they aren't for everyone, but there are ways (Ohlins bumpers, CC Tigon, SV8 HBO, etc) to deal with that in the shock as well, but I still understand it's not necessarily an ideal feeling for some riders. I'm mainly on natural, rough eroded terrain and find the tracking of the bike to be really nice, and similar to Perry's (likely excessively humble given he had barturns in ever photo of the review) self admission of not getting airborn much, I'm staying mostly on the ground unless I have to. If I were forced to identify an issue with the bike right now, it's mainly that pedaling over flat, rough traverses is a bit more work because it appears the rear of the bike sortof locks up under pedaling force, but I've found how to adapt and move myself around to work with this and find it can be used efficiently once you learn it.

I'm putting more time on the bike once I recover from surgery and an antibiotic allergic reaction (it's been a fun 2 weeks....), so I'm going to actively be trying to feel for these things and hopefully getting on more varied trails than I was before, but as of right now, I see few downsides to the Starling compared to multipivots I've owned. I struggle to reconcile this with the engineering I understand between the two, but we'll see as time goes on.

Reply

Mike Ferrentino

4 months, 3 weeks ago

"the linearity..." nicely phrased. I have had trouble in the past, most easily identified with Devinci or Transition test bikes, of not being the type of rider who could use all the travel on tap because it would get so rampy at the end of stroke. I acknowledge this about my own riding - I tend to ride soft, and tend to set my forks up softer than most guides, and am that guy who usually backs the compression adjusters all the way out. Some of that is that I am not a pro downhiller, some of that is that my riding style is more carve than smash. To each their own. I think it's great that people are building bikes that allow riders to hit shit so hard that they crumple rims peel off tire sidewalls, and the suspension keeps on keeping on.

I also appreciate a bike that lets me use most of the travel and still manages to handle really well and feel really civilized. And no, I've never once in my life wondered if brake jack is ruining my ride.

Reply

JT

4 months, 3 weeks ago

Refreshing to read someone acknowledge where they are in a bike's use class scenario. Honesty is a well under appreciated item in reviews. Thanks for keeping that part of you MO, Mike.

Lu Kz

4 months, 3 weeks ago

This is a somewhat unfounded opinion as my sample size is exactly one, but I think there's value in the single pivot designs for intermediate riders trying to improve. I never really worked on my "race braking" versus schmuck braking until I got on a bike that was like "oh hey, you shouldn't be braking here". I honestly think riding bikes that isolated those forces particularly well allowed me to lean on the crutch that was the suspension design and had little need to develop and improve on brake skills. Now I can go back to those old designs and my good habits stick with me.

Reply

JT

4 months, 3 weeks ago

I absolutely adored the versatility of my 03 Bullitt. Dual crown, sure, single crown sure. It may have been optimized sus wise around a 42t chainring, but it handled a 32 without much of a complaint. But I was also 20 years younger and didn't mind pedal kickback near as much as I seemingly do. It still rode like a big ol full squish BMX bike with slacker geo. I am still very intrigued by the Foes Ridgeback. Brent has been freak flag waving the joy of a proper single pivot bike for ages. It took the steel builders to show the old nutter may be on to something. To say nothing of his hydraulic repair stand he was pimping a decade+ ago for use on heavy DH rigs.

Reply

Lu Kz

4 months, 3 weeks ago

It wasn't immediate, it was... one hour.

Reply

Danksi

4 months, 3 weeks ago

Our local tuning shop convinced me to give this shock a try, it’ll be a leap of faith and I’m mainly in it for the extended service internal of the SV-8. 500hours or 12months, that’s way better than the 100hours I only just about get with the X2 I have currently. My magic spreadsheet helped justify the extra $.

Reply

Pete Roggeman

4 months, 3 weeks ago

Curious about this magic spreadsheet you speak of...

Reply

Adrian Bostock

4 months, 3 weeks ago

I spent some time in Hurricane/ St. George (mostly Hurricane area) recently with new fork on my bike. I had done a couple rides before hand in sub 0 temps on frozen trails, which is terrible conditions to set up a fork. Heading down there I thought I would spend some time dialling in the fork while riding. In the end I did not feel the need to play around with my suspension setting much at all. you have some G outs at the bottom of some rock rolls and you want a mid stoke support for some of the short steeps, but there are not many long fast chunky down hills where you feel your suspension.

don’t get me wrong, I had a great time, would ride there again, just would not go there to test out suspension settings. It highlighted to me how location specific suspension setting and requirements are.

Reply

Mike Ferrentino

4 months, 3 weeks ago

Yep. In my case, it was the first non-frozen riding opportunity, so that's what it was. Lots of spots to get a little air on relatively buff trails, some good mid-speed rocky stuff as you described, and there are places out beyond Hurricane where you can work the high speed stuff but they were snowed in on this trip and my time was limited. Santa Cruz has some good variety, but the more gnarly jump lines in the woods there these days is well above my pay grade. Still, a totally different environment than St George. Which is a totally different environment than (insert name here...)

Reply

Kos

4 months, 3 weeks ago

My, how far Darren has come from his Romic days.

Slap a climb lever on this, and I'd be calling with a CC.

Reply

JT

4 months, 3 weeks ago

I decidedly know I am not the target market for Push's wares due to a. DIY Dirty Ol' Mech that I am and b. frugality. Their gear looks the bees and the praise for it is likely justified. I do wonder, and this just ain't a Push wondering, how hard it would be to make bleed ports on a damper so that near anyone could do a quick bleed on it without having to tear it down to the bones. I understand the basic reasoning of a full rebuild after xxx amount of hours, but I think if a shop/end user could perform a damper bleed easily tear down intervals could potentially be lengthened. Push using a N charge on their IFP likely figures into that, but for a shop a small tank and regulator can be had for a pittance, all things considered. I've rebuilt a few dampers where the oil was pretty much new when emptied, and that was kind of a bummer, time wise. Having bleed ports would let a mech get a lay of the land before tearing it apart. Clean fluid? Bleed, charge, and go. Brackish fluid? Full tear down.

One last bit: Anyone griping about brakejack on a modern single pivot didn't spend enough time riding a 150mm Cove G Spot in the Northeast. Damn was that the scariest bike on fast chunk.

Reply

Timer

4 months, 3 weeks ago

I’d guess that at the point where you would consider changing the damper oil, the seals need replacing anyway. So there wouldn’t be much reason to have the ability to bleed the damper from the outside?

Reply

JT

4 months, 3 weeks ago

Kicker is that doesn't apply to forks, at least in my neck of the woods. I've had damper fluid smoked, but the fork is running fine until it gets hot. The seals are still sealing. Now if you take a part that has a higher velocity cycle count (a rear shock), but make it so you can bleed it without having to introduce another variable (mechs ability to seat seals and avoid damaging em) it seems you could take the full tear down/seal swap out of the equation, at least longer than current. That seems like a great sales option from an end user/mech perspective.The number of old Hayes and Avid hydros I've bled where the fluid is wayyyyy contaminated but the brake still somehow works until it gets hot is pretty similar. If you have an option that allows for easy bleeding, that makes it easier to perform and/or sell the service. Anyone from a sus co that wants to correct the ignorant here is welcome to. I'd rather know than not.

Reply

Velocipedestrian

4 months, 3 weeks ago

I heard a podcast with Vorsprung Steve, who when asked if he could magic up an instant change in suspension nominated a spyglass in fork lowers. He suggested people might be more likely to get things serviced if they could see the fluid colour.

Reply

Please log in to leave a comment.